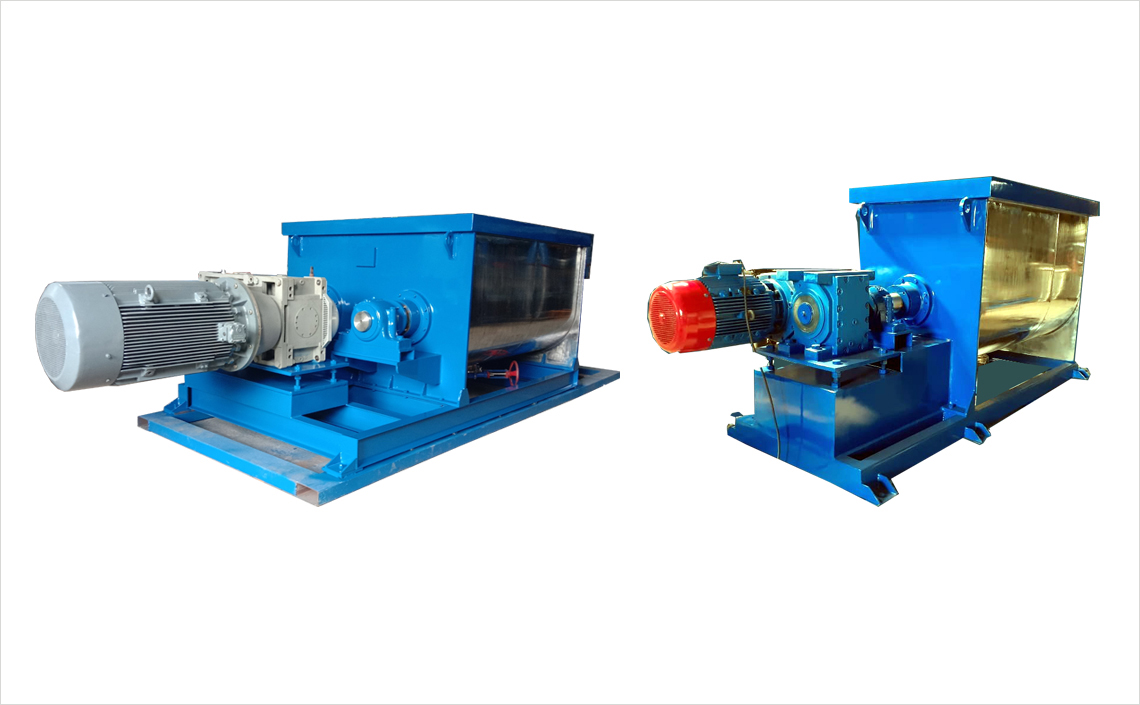

PUG Mixer

Get Free Quote

Get Free Quote

A pug mixer is a type of mixer which is used for products which have very high viscosity and require the blending of powders in liquids. They are also referred to as paddle mixers. Their heavy-duty construction along with their-U-type trough design makes them an excellent choice for agglomerating, mixing, or conditioning in demanding settings. They are available in single shaft and dual shaft designs. Rotating shafts with pitched paddles to create a kneading and folding over motion inside the trough. Both ends of the shafts are provided with stuffing boxes which prevent the leakage of materials from the shaft seal and avoid bearing damage.

Pug mixer inner walls are constructed of SS or MS sheets. The mixer consists of a centre shaft of appropriate diameter and is either made of S.S or M.S material. The centre shaft is fitted with specially designed agitator blades in order to provide contraflow action. Contraflow ensures constant circulation of mix/blend ingredients from one end to another to homogenise the batch.Both the ends of the vessel are provided with stuffing boxes on the shaft. Blend ingredients are prevented from leaking and entering into bearings by the stuffing box. The shaft is supported by heavy duty pedestals.

For models below 300 kgs the unit is provided with a pulley drive system along with tilting arrangement for discharge. For models above 300 kgs the unit is provided with a gearbox drive coupled to a motor and the discharge valve provided at the bottom.

Range of Products :

* Sigma Kneaders * Ribbon Blenders * Attritors * Ball Mills * Hydraulic Dissolver * Planetary Mixers * Batch type Sand Mills * Conical Blenders * Continuous Sand Mills * Resin Plants * Bead Mills * Turnkey Projects

Applications :

* Varnishes & Paints * Resins, Glues, Adhesives * Polyurethanes * Pharmaceutical Products * Colourants * Chemicals * Inks * Lacquers * Foods * Cosmetics

Features :

- ∘ Available in sizes upto 20 tons.

- ∘ Easy charge and discharge mechanis

- ∘ Can be designed as a standalone unit with screw feeders for raw material inlet and automatic packing system for the processed material.

- ∘ Very efficient mixing for thick materials

- ∘ Very easy to clean. Available in MS / SS

- ∘ Best suited for Distemper, Polyester Putty, acrylic putty etc.

- ∘ Available in double shaft design for improved mixing efficiency